High precision in dimensional tolerances.

Technical support provided from the time of development and design.

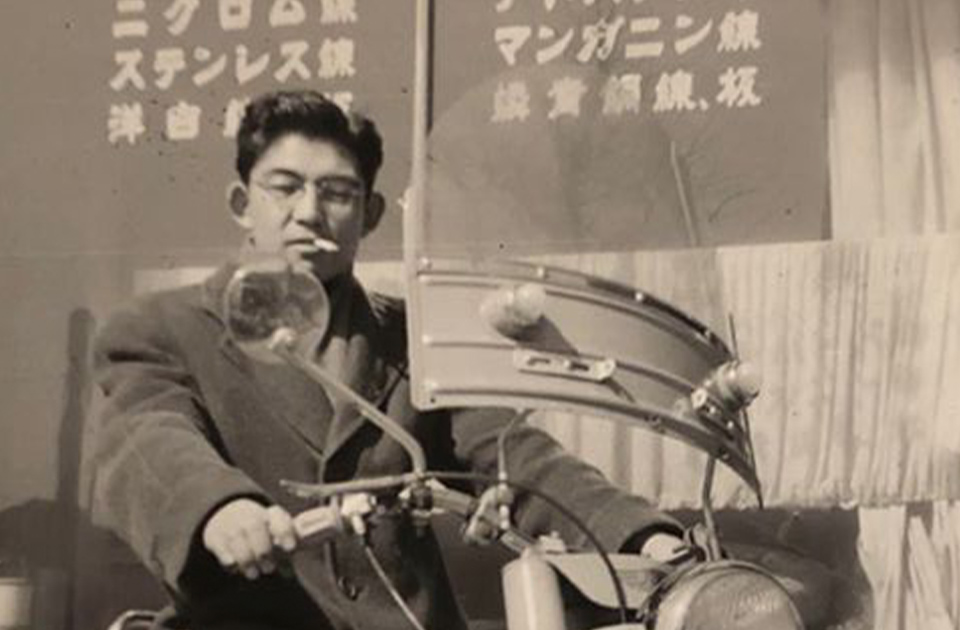

Companies and research facilities using Tokyo Resistance Wire's special alloy fine wires (such as Nichrome, iron-chrome, copper-nickel, iron-nickel, pure nickel, and manganese-nickel)

are incredibly diverse, spanning several hundreds both domestically and internationally.

Resistance wires are widely used in a variety of applications, including electronic components and devices like smartphones, industrial machinery, automotive electrical components, air conditioners, control parts around radiators, heaters, and electric furnaces.

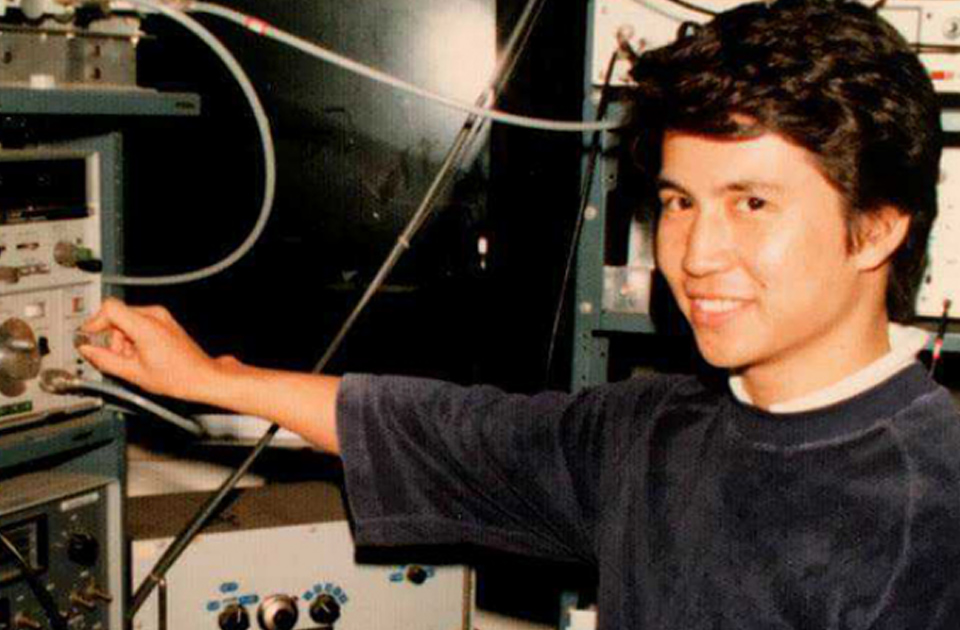

Since its founding, the company has utilized its experience in providing technical guidance to major manufacturers to develop custom processing equipment. This allows for the creation of products that meet specialized requirements. With processing technology and know-how capable of meeting stringent demands, the company supports product developers and researchers, offering consultation and backing in product manufacturing.

The company regularly conducts strict calibration management of the diamond dies necessary for drawing metal wires, refining them with high precision to the 1/1000 mm. This meticulous process ensures the manufacturing of more accurate resistance wires.

Top Page

Top Page Access map

Access map Recruit

Recruit Contact Us

Contact Us