Products Manufactured

The process and equipment for producing ultra-fine wires at the micron level of precision.

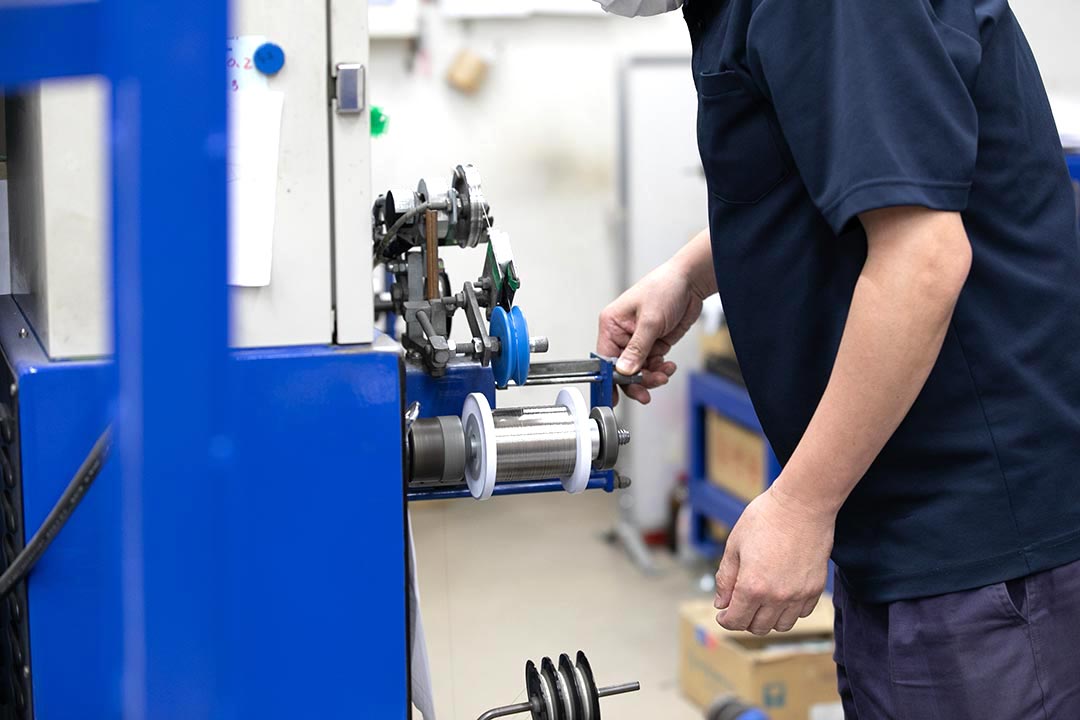

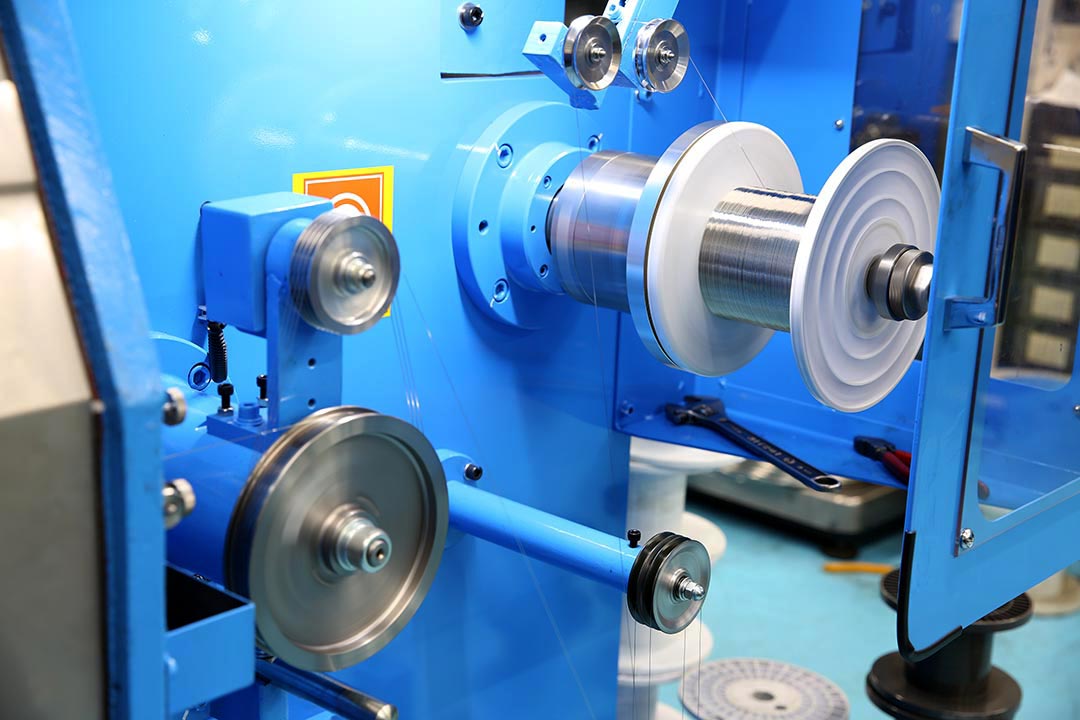

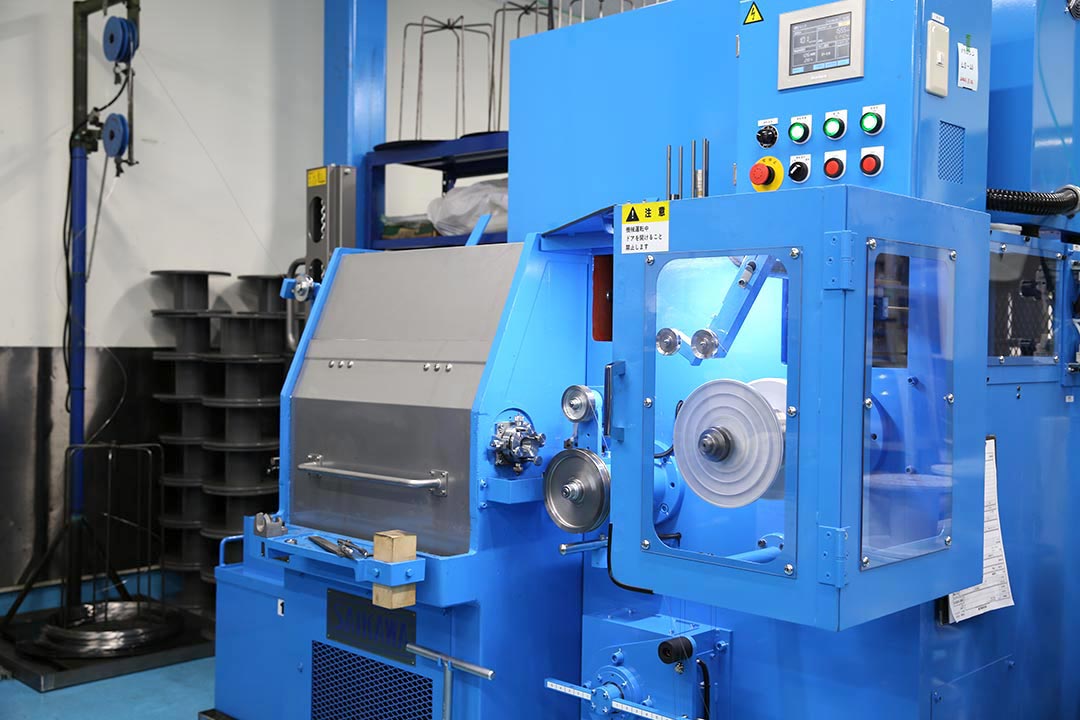

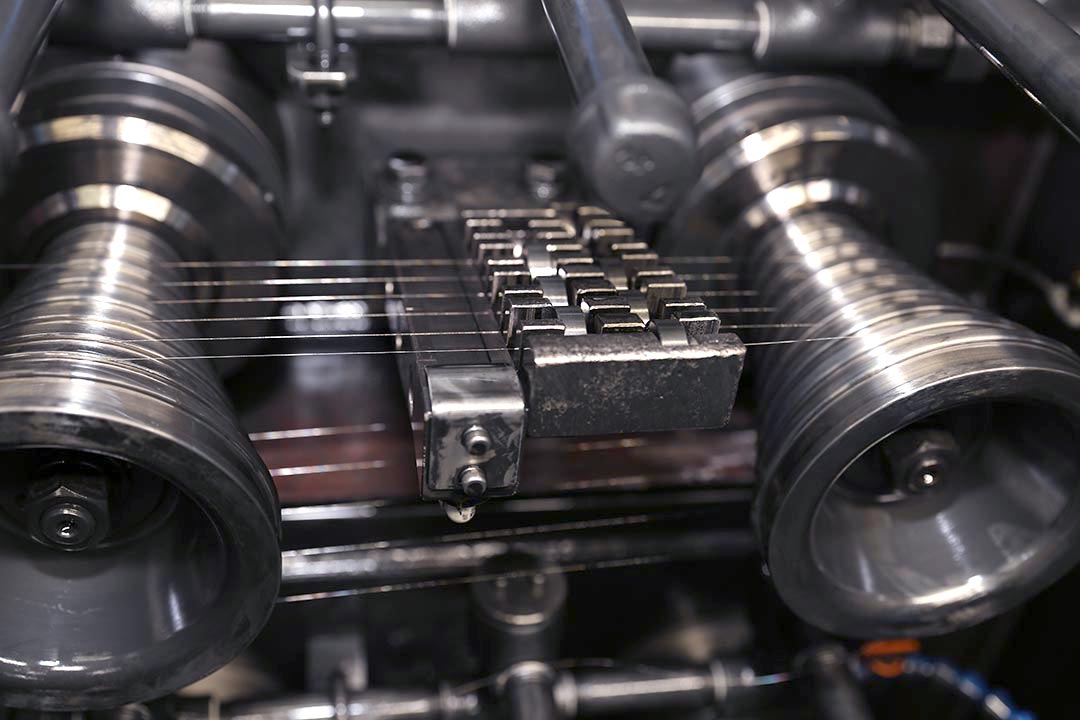

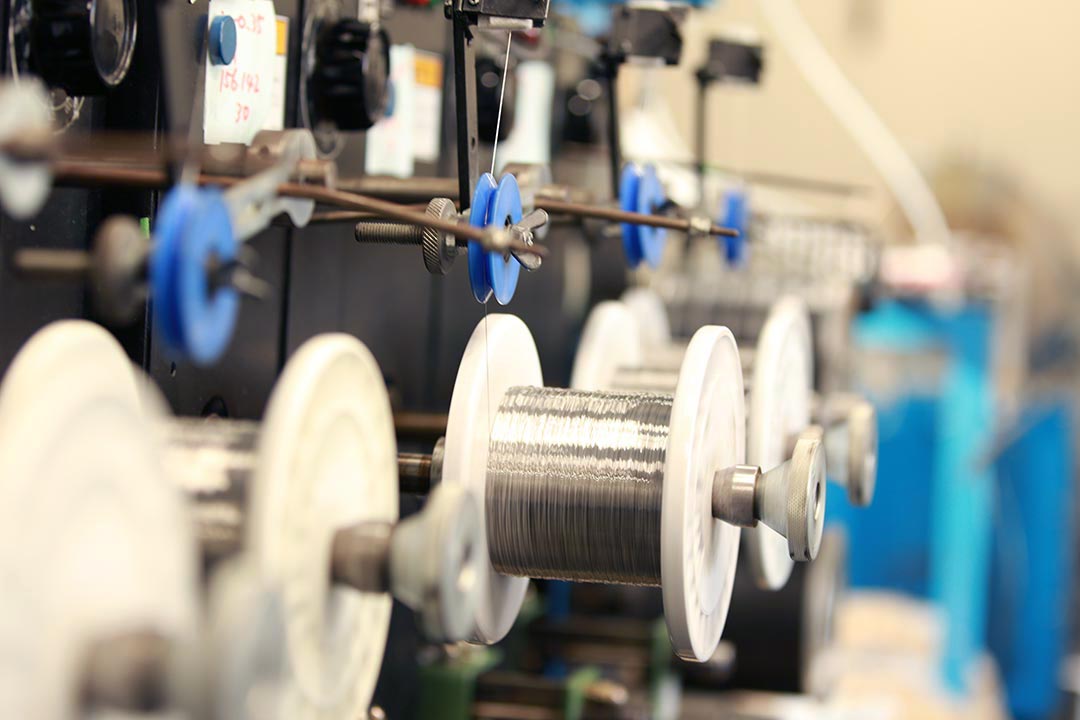

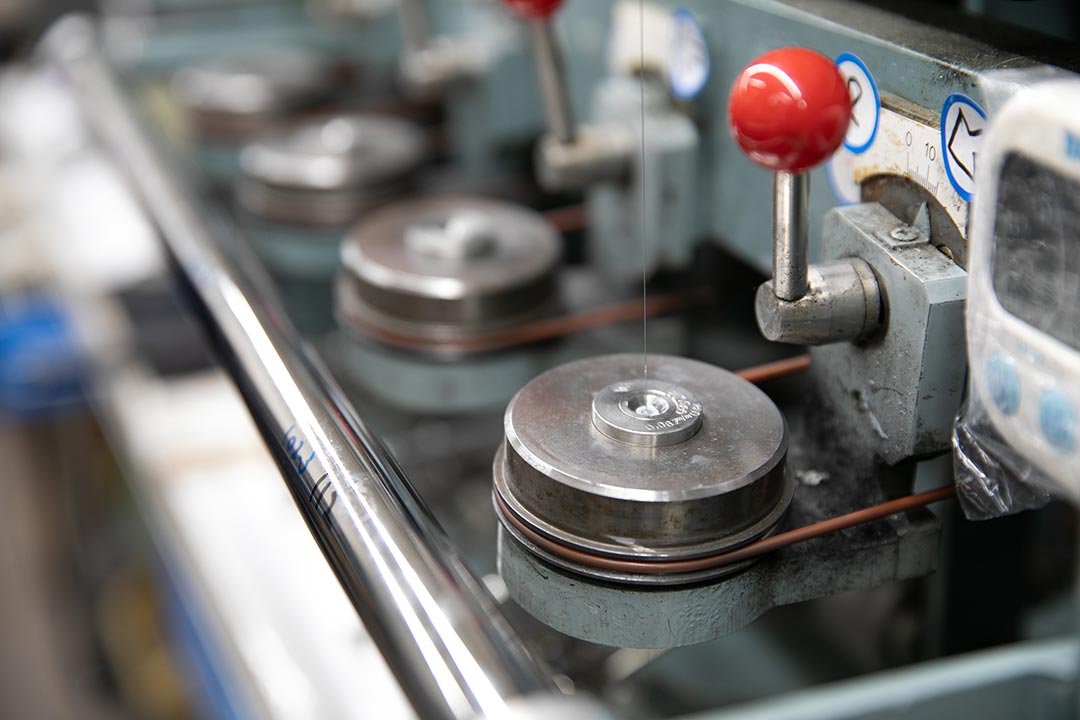

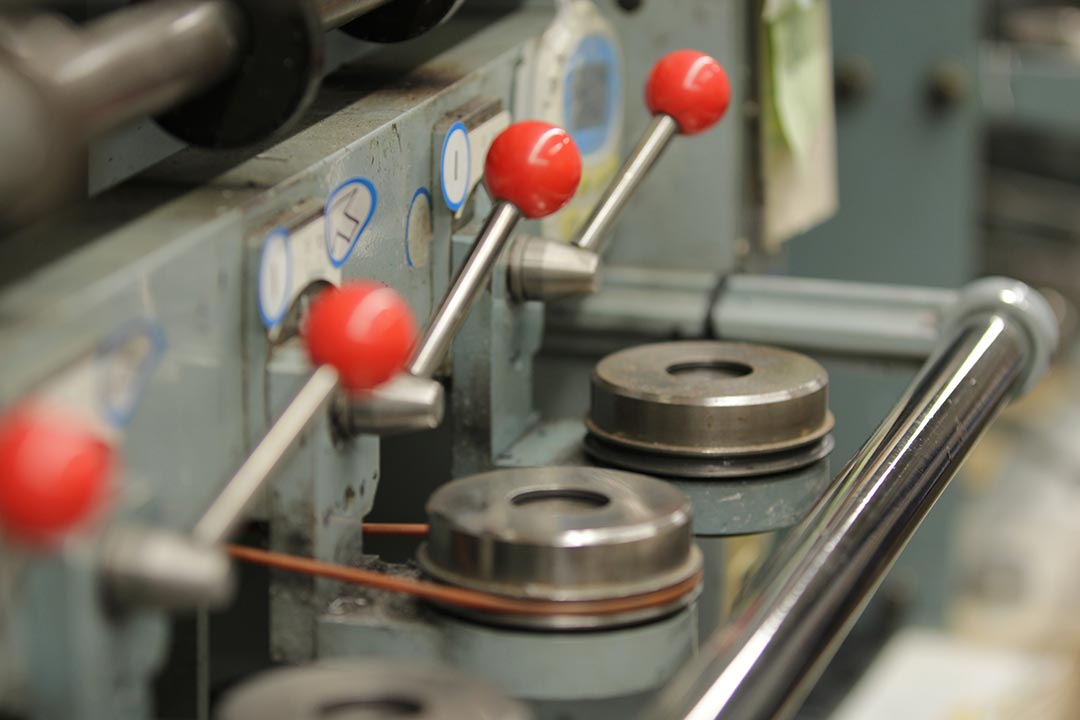

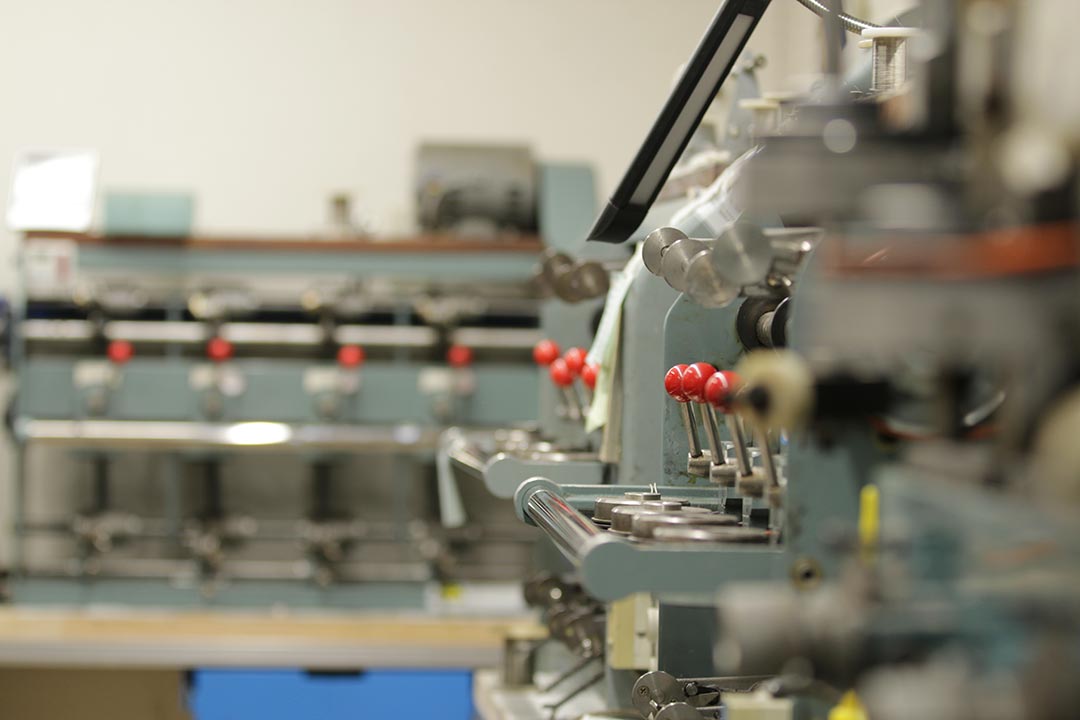

Continuous Wire Drawing

Continuous wire drawing is a process in which metal wires are elongated by pulling them through diamond dies with small trumpet-shaped holes. A slightly thinner wire than the mother wire is threaded through a hole, and by pulling it at a constant reduction ratio, a finer metal wire is produced. Multiple diamond dies are set on a single wire drawing machine, allowing the metal wire to continuously pass through them, gradually refining its thickness.

In the production of resistance wires, this becomes one of the most fundamental and essential operations. Tokyo Resistance Wire employs 20 continuous wire drawing machines, customizing the manufacturing process based on customer applications, steel types, and specifications.

| Wire drawing machine models | The number of units in possession |

|---|---|

| Wire drawing machine for thick to medium wires | 10 units |

| Wire drawing machine for thin to ultra-fine wires | 10 units |

| Vertical drum-type wire drawing machine | 1 unit |

To create resistance wires that pass through dies of different sizes without imposing stress and achieve uniformity, an exceptional level of technical expertise is required. Therefore, adjustments are made to consider the torque applied within the wire drawing machine and the varying distances resulting from the extension of the winding wire.

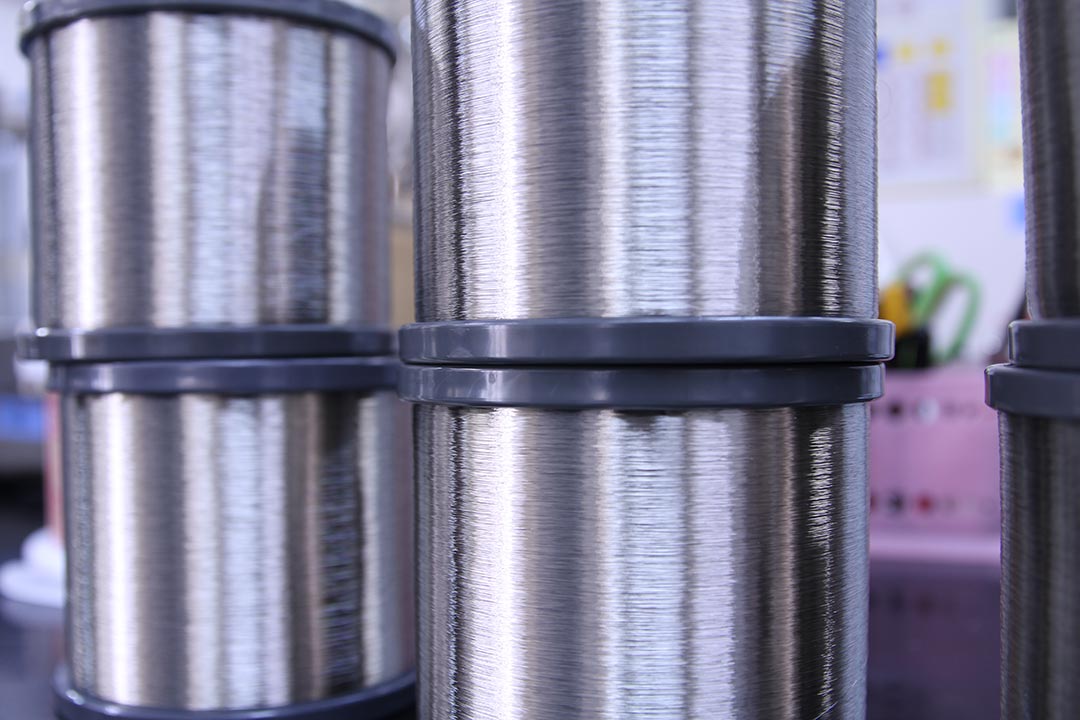

Wires are wound on spools of different sizes, and with careful consideration to maintain uniform tension, resistance wires are manufactured.

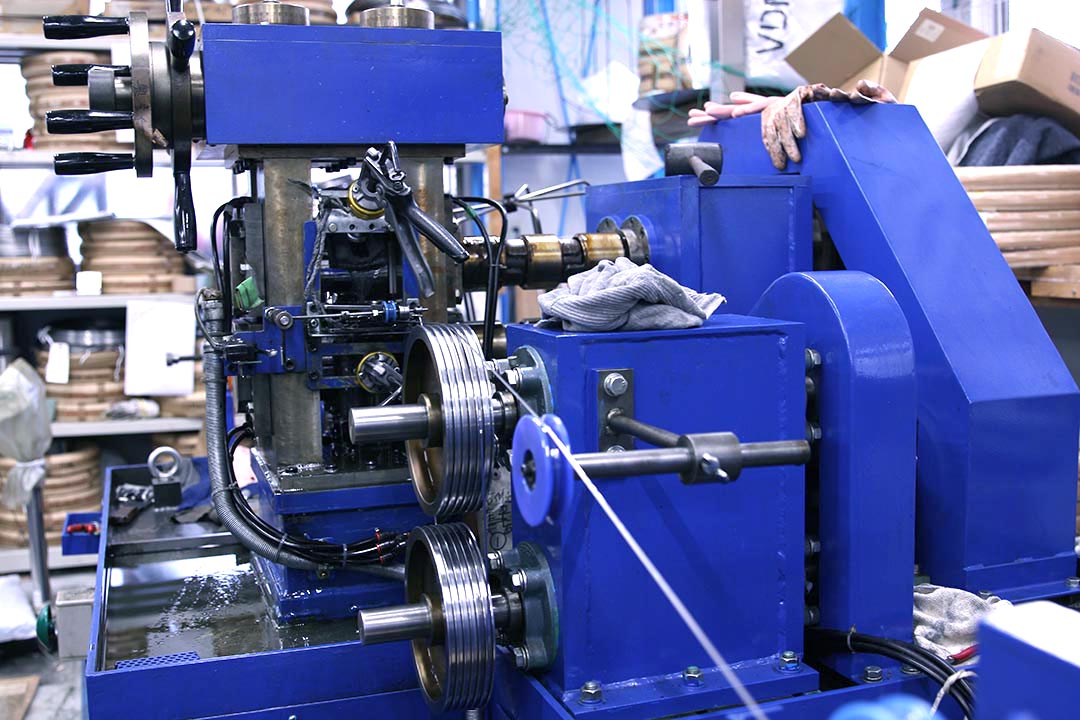

Rolling Process

Rolling processing involves passing metal wires between upper and lower sets of carbide rolls to flatten and shape them into a strip. This process is repeated multiple times, gradually reducing the thickness of the strip and adjusting its width and thickness, as well as the conductor resistance.

| Rolling mill | The number of units in possession |

|---|---|

| A rolling mill larger than 120 φ in diameter | 4 units |

| A rolling mill larger than 95 φ in diameter | 1 unit |

The mother wire is also processed with greater precision by using materials elongated in-house to the 1/1,000mm level. It finds applications in various uses such as flat strips for catheters, electronic tubes, resistance materials, and electric heaters.

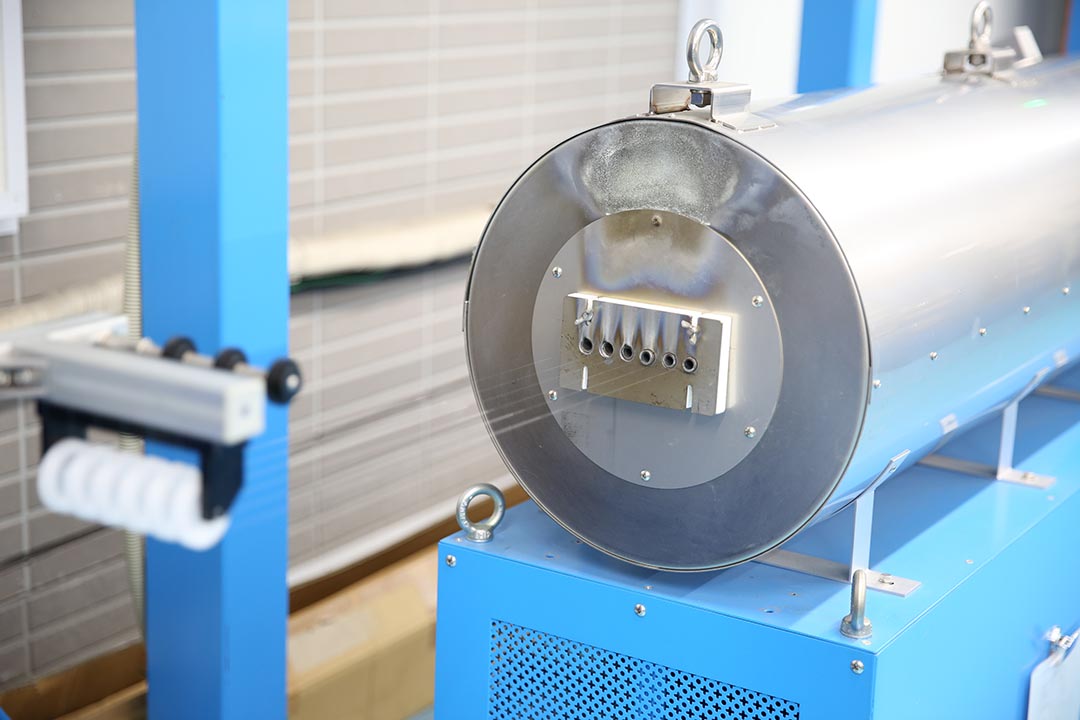

Heat Treatment

The heat treatment process is the process of finishing electric heating wire, resistance wire, and various metal wires and strips.

One of the features of the processing of Tokyo Resistance Wire is that the wire is passed one by one through a long special heat-resistant alloy pipe and then bright annealed (BA) while the wire is running.

In this process, the annealing temperature varies depending on the type of wire, but for high temperature wires, the environment is around 1,000℃.re.

| Electric furnace | The number of units in possession |

|---|---|

| Phase-controlled traverse Kantal system | 7 units |

| Blue Line Use | 1 unit |

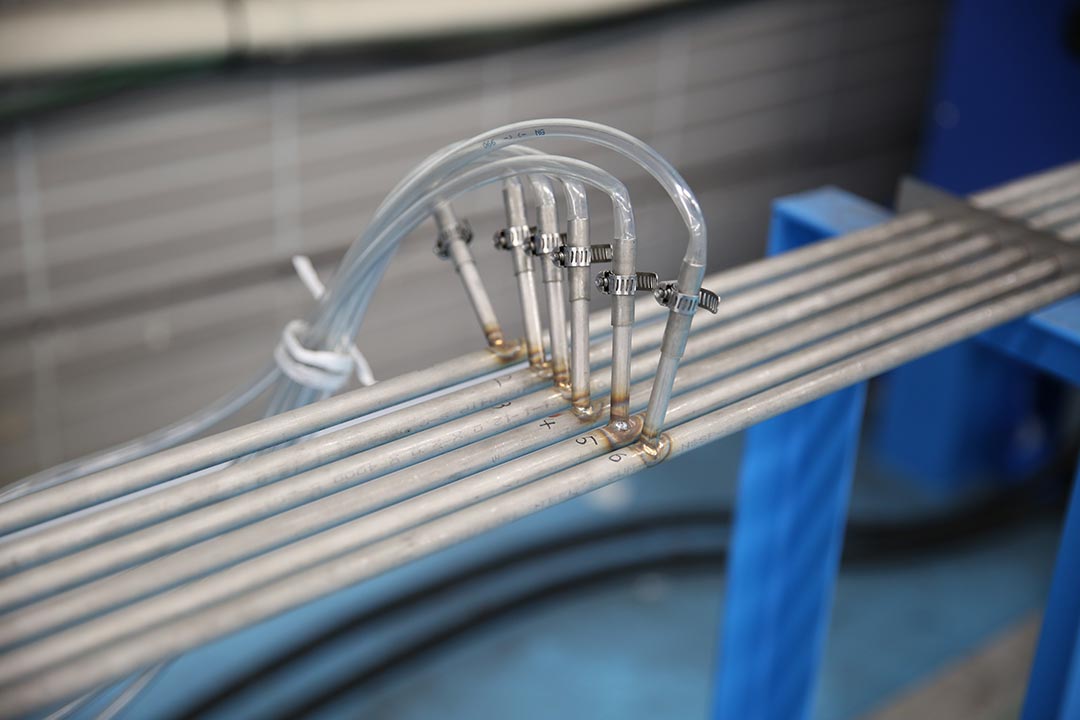

In order to prevent the metal wire from oxidizing in this environment, redox gas are used into each pipe and traveling annealing is performed in the gas atmosphere. The purpose of traveling annealing is to stabilize the product quality.

For very thin wires, called fine wires and ultra-fine wires, we use a bobbin traverse winding system to achieve uniform winding.

The winding and unwinding devices are dancer controlled in an electric furnace at a constant wire speed and tension to ensure stable operation from the beginning to the end of the winding.

Heat Treatment Winding Process

| Winding machine | The number of units in possession |

|---|---|

| Annealing Ultra-Fine Wire Size 6-Unit Bobbin Traverse | 1 unit |

| Annealing for Thin Wire Size 10-Units | 1 unit |

| Annealing Intermediate Size 5-Units + 3-Units Bobbin Traverse | 1 unit |

| Annealing for Intermediate Size with 6-Units Bobbin Travers | 1 unit |

| Annealing for Intermediate Size with 8-Units | 1 unit |

| Annealing for Thick Wire Size with 4-Units Bobbin Traverse | 1 unit |

Cleaning Process

| Cleaning Equipment | The number of units in possession |

|---|---|

| Ultrasonic Cleaning Machine | 4 units |

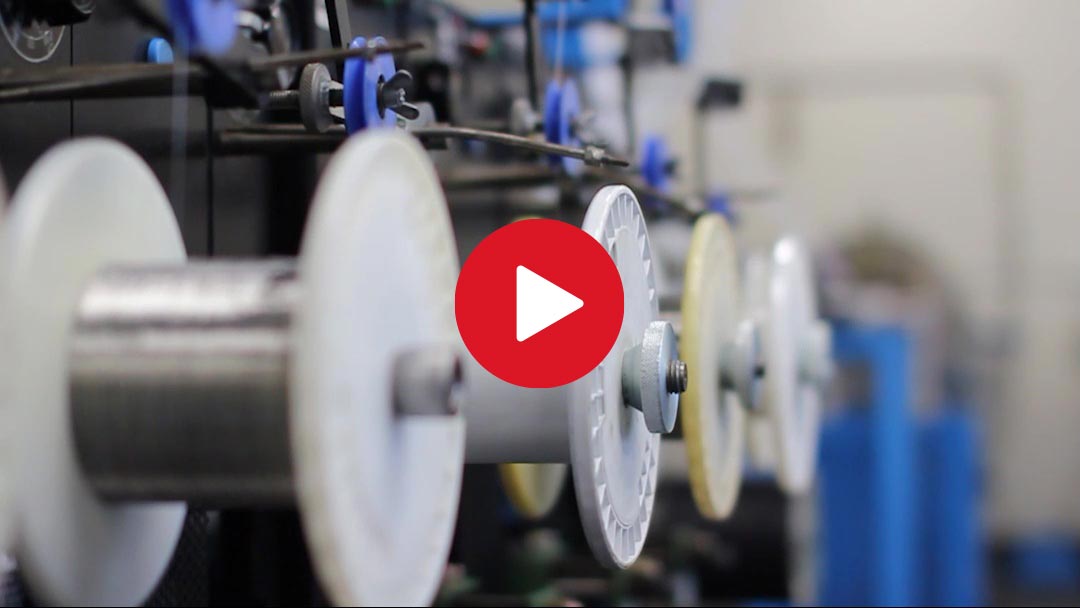

Finishing Winding Process

The bobbins are winded according to the specifications specified by each customers such as bobbin type, winding volume, etc.

Meter winding control is also available with a precise meter counter.

| Winding machine | The number of units in possession |

|---|---|

| Ultra-fine to Fine Wire Size Bobbin Traverse Winding | 5 units |

| Fine to Intermediate Size Winding | 9 units |

| Intermediate Size Bobbin Traverse Winding | 1 unit |

| Intermediate Size Winding | 1 unit |

| Intermediate to Thick Wire Size Winding | 2 units |

| Fine Wire Size 5-Unit Winding | 1 unit |

| Strip Winding | 3 units |

| Coil Master Supply | 1 unit |

For fine wires and ultra-fine wires, we utilize a bobbin traverse winding device. The equipment records and manages constant wire speed, constant tension, and winding pitch, ensuring consistent winding conditions for each steel type and wire diameter.

Spiral Processing

In spiral processing, we primarily engage in manufacturing products used for "electric heaters." We undertake the production of various materials such as Kanthal wire, iron-chromium electric heating wires, nickel-chromium electric heating wires, etc., catering to different applications based on a rich variety of material types and wire diameters. We propose the most suitable processed products by taking into account specified requirements such as arbitrary outer diameter dimensions, voltage (V), power (W), characteristics, lead length, twisting, and more.

| Spiral processing machine | The number of units in possession |

|---|---|

| Fully automatic winding machine | 2 units |

| Manual winding machine | 3 units |

Spiral processing carried out by skilled artisans allows us to accommodate small-batch manufacturing that cannot be achieved by machines alone. Additionally, we can accommodate various shapes for leads, including length, orientation, centering, and more.

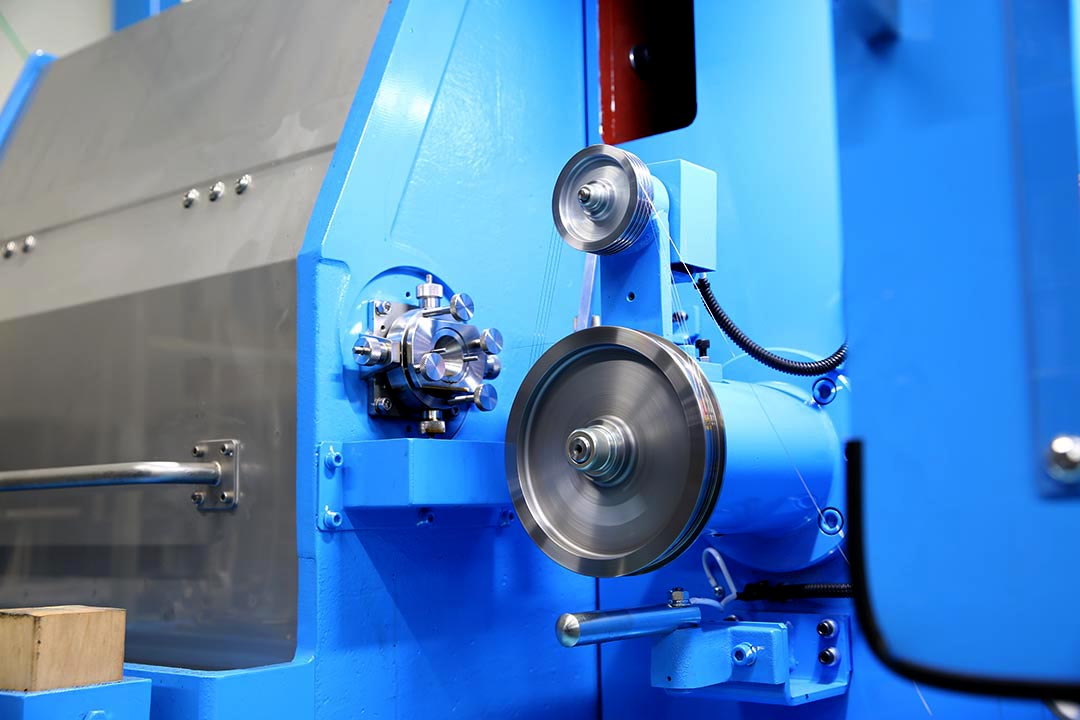

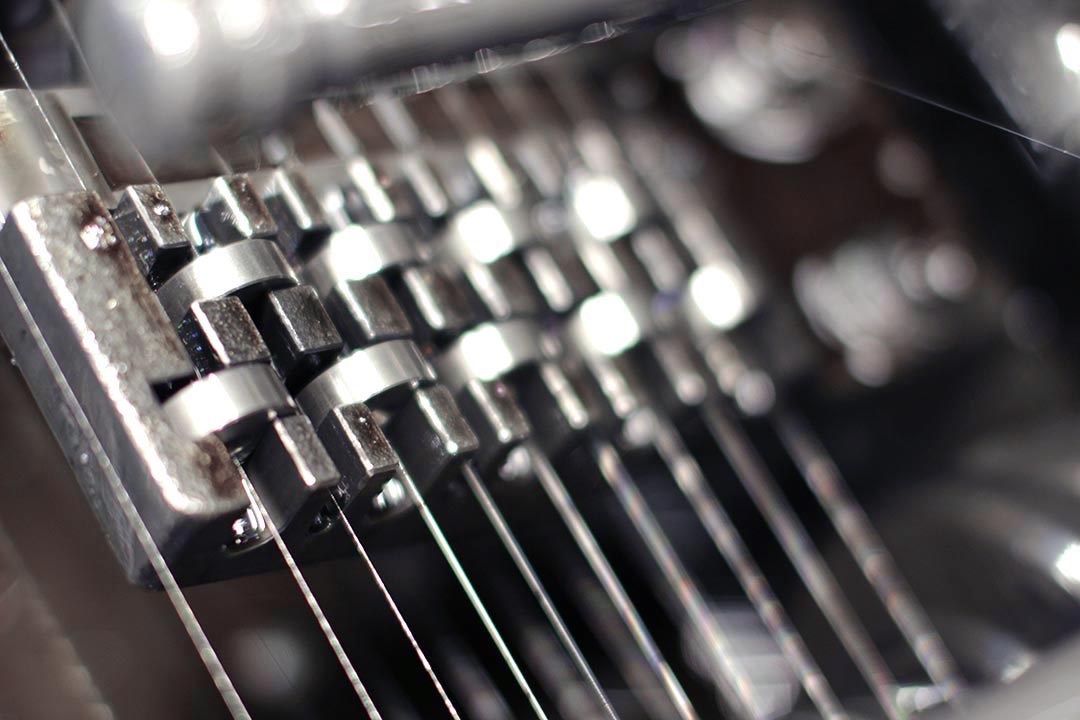

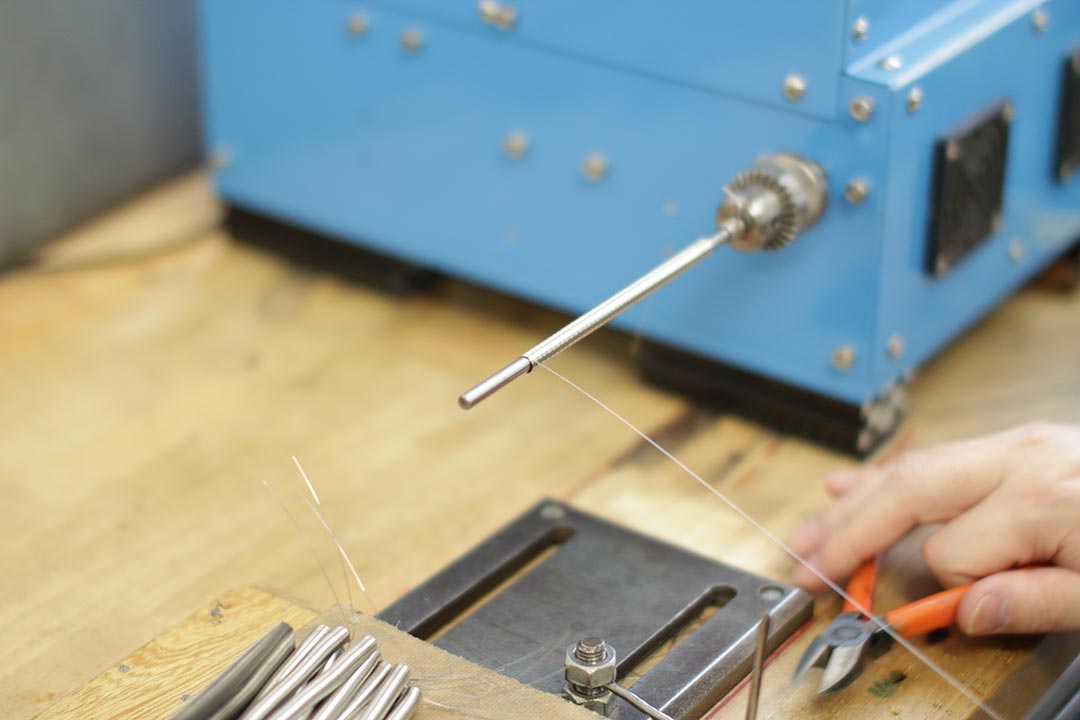

Diamond Dies Polishing

Diamond dies polishing is a process of grinding and polishing diamond dies used to shape metal wires into fine lines during wire drawing. The precision of the holes in the polished diamond dies is extremely high, reaching as fine as 1/1,000 to 5/10,000 millimeters.

| Polishing machine models | The number of units in possession |

|---|---|

| Diamond dies polishing machine | 5 units |

Polishing allows for meticulous control over wire diameter and conductor resistance, enabling the production of more precise resistance wires.

In diamond dies polishing, metal wires passed through the holes are adjusted vertically over time using a polishing agent containing diamond particles, achieving the desired size. Furthermore, the die itself is rotated to perform uniform polishing with a perfect circular and tapered shape.

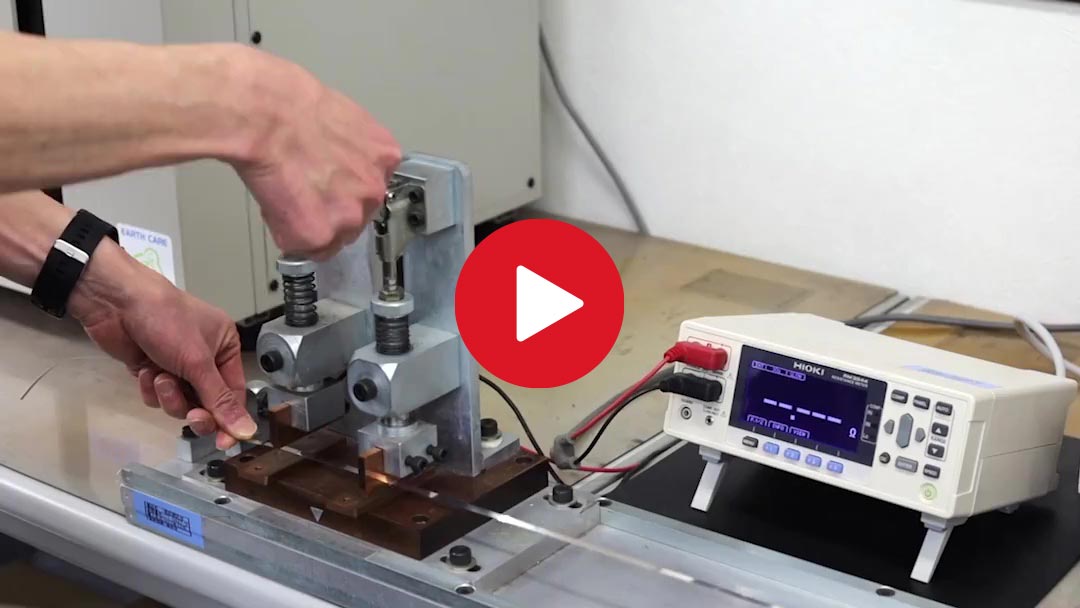

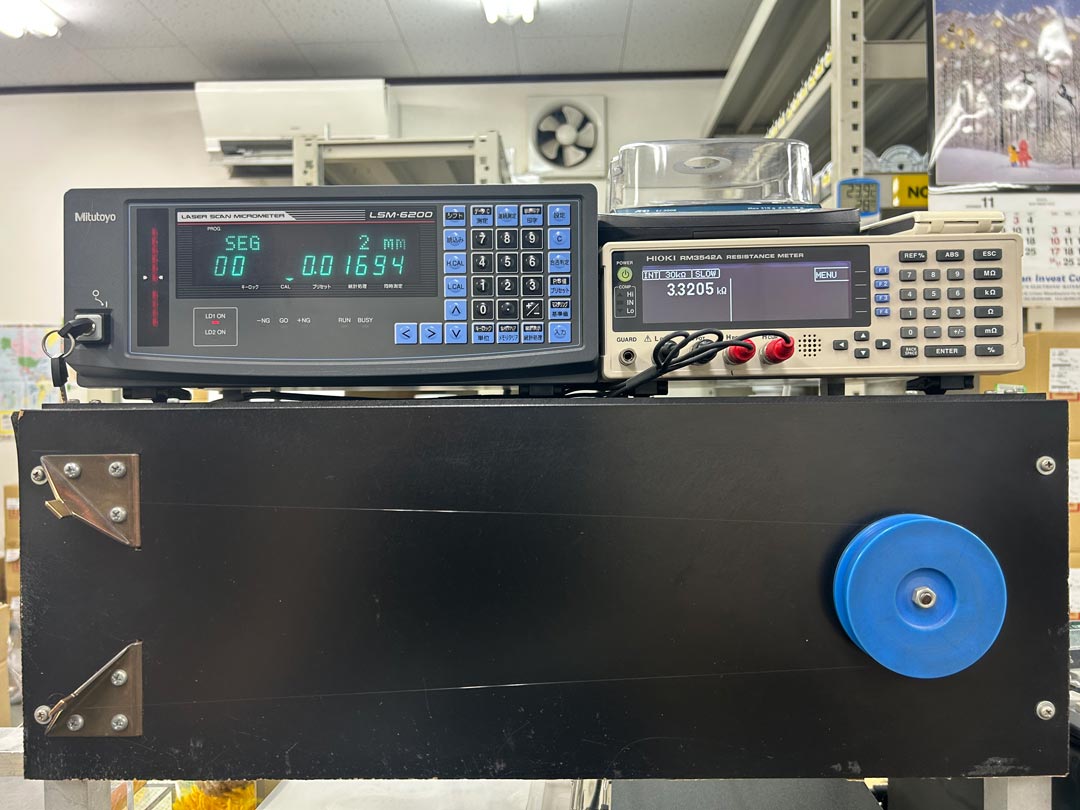

Product Inspection

We conduct a comprehensive inspection management for each bobbin using our in-house developed computer resistance inspection system. Special specifications unique to each customer are recorded in the computer, allowing data to be read from measuring instruments and automatically determining compliance with the set conditions.

| Testing and Measurement Equipment | The number of units in possession |

|---|---|

| Resistance Wire Automatic Management System | 1 unit |

| Resistance Meter | 9 units |

| Tensile Testing Machine | 2 units |

| Weight Scale | 18 units |

| Low-Temperature Constant Temperature Bath | 1 unit |

| Digital Micrometer | 22 units |

| Laser Outer Diameter Measurement Device | 1 unit |

| Electron Microscope | 1 unit |

| Optical Microscope | 1 unit |

Measured data is managed in lots, and past measurement data is also recorded and saved for retrieval.

The inspection can include dimensions (wire diameter), conductor resistance, volume resistivity, tensile strength, elongation, temperature coefficient of resistance, weight, meter count, and other items as needed.

We also have a large inventory of products in stock, so we can provide products from stock on the same day.

In cases where a small quantity of resistance wire is needed for prototypes or similar purposes, we provide it in increments of 10 meters if it is available in stock.

Finished Products

Products created with our in-house proprietary technology are used in a wide range of applications, including automotive components, smartphones, and various other products.

Top Page

Top Page Access map

Access map Recruit

Recruit Contact Us

Contact Us